Onsite Services to Industrial Customers

The world has never faced as many social and environmental challenges as we do today. By focusing on sustainability and efficiency, Veolia Southern Africa can help industrial clients optimise their operations and reduce their environmental impact. From water treatment to the oversight and management of energy assets, our onsite industrial services cover a diverse range of services including total waste management, industrial water management, multi-business services and industrial energy services. With extensive expertise and innovative technologies, Veolia Southern Africa can collaborate with any stakeholder to create customised solutions that meet each client's unique needs and help improve their overall performance.

Water, for example, is a critical component in the production cycle of countless industries. Yet these systems do not always operate optimally. Our onsite industrial services at locations across Southern Africa have helped our industrial clients address a wide variety of water-related challenges. As residents of a water-scarce, corner of the planet, maximising the value we get from our water use is especially important.

Our complete range of technology and implementation solutions include full-service operations and maintenance, with a footprint that extends into the African continent with sites in Namibia and Botswana.

Key offerings:

- Cooling Tower Optimisation

- Operating Contracts

- Zero Liquid Discharge (ZLD)

- Waste Treatment and Optimisation

- Anaerobic Digestion

- Financial Engineering and Site Assessments

- Asset Management and Mutualisation

- Hubgrade and Performance

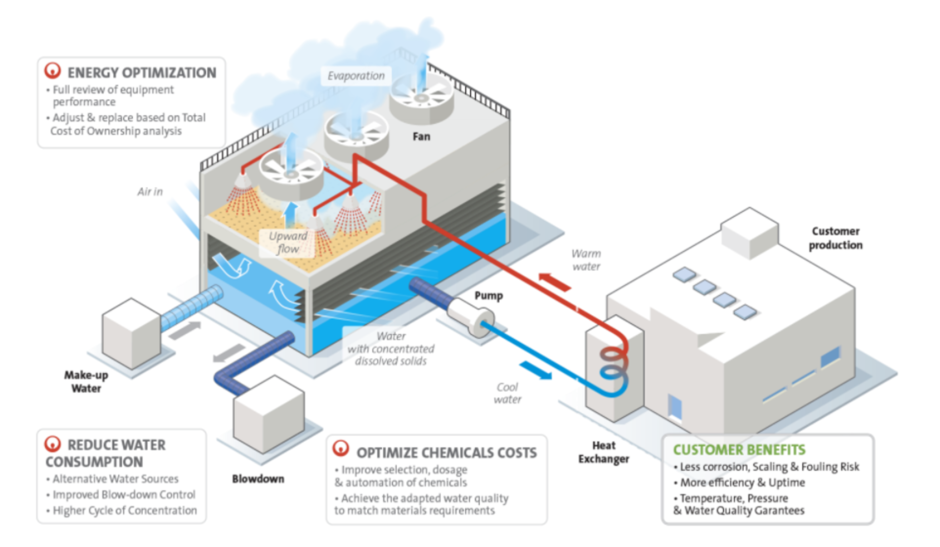

Increasing concerns for water conservation has resulted in new demand for water reuse programmes with industrial players relying more and more on re-circulating systems with cooling towers, spray ponds or evaporative condensers to dissipate heat. Such systems allow for extensive reuse of water and reduce reliance on make-up water.

The most common type of equipment used to dissipate heat with water is the cooling tower, of which there are various kinds used to increase the contact of water and air. Both industrial and commercial operators of cooling tower systems know how critical it is to keep their systems running efficiently and reliably. Cooling tower systems are used to remove heat from both manufacturing and utility processes, which can impact both production efficiency and employee working conditions. A thorough understanding and control of the water used in a cooling system is necessary for optimizing its operation.

Veolia helps clients extend the life and improve the efficiency of their cooling tower systems through an integrated approach of chemicals, equipment and services.

FAQ's

What is a cooling tower?

A cooling tower is a heat exchange technology that allows water to cool through direct contact with air. The technology uses a special process, which creates a cooling tower cycle using limited water evaporation to maintain the water's temperature at the desired level. Cooling towers are typically used to provide a stable and cost-effective way to cool various systems. Some examples of how this type of tower can be used include heating, ventilation, and air conditioning. However, cooling towers also have applications in various manufacturing processes that require maintaining stable temperatures and safely reducing excess heat. One of the reasons why cooling towers have become so popular is their cost-effectiveness. They are relatively cheap to install and maintain, and the operating costs make them an excellent choice in many situations. What's more, the technology uses a process that makes it very reliable, which is essential in situations where temperature fluctuations are not an option. However, for the process to work, cooling tower water treatment best practices must be followed. That is the only way to avoid damaging the system and remove damaging impurities such as dissolved solids. When the water evaporates, impurities are left behind, a process known as the cooling tower cycles of concentration. With every cycle the system goes through, this concentration increases. This is when cooling tower chemical treatment becomes necessary.

How do Cooling Towers work?

There are many different types of cooling towers, each with its own principles of how the heat is transferred from the air into the water. Although there can be many different possibilities, let's explore some of the common principles that make cooling towers such a great way to transfer and control heat. Most cooling towers use a process known as evaporative cooling, which heats the water at the top of the cooling tower by sending hot air towards it, evaporating some of the water, and transferring the heat in the process. The hot air then naturally rises out of the cooling tower, allowing it to maintain a stable temperature and cooling the remaining water. One of the most important aspects to consider when looking at this type of process is the cooling tower water treatment. Since water contains dissolved minerals, those accumulate as the water evaporates. This means regular maintenance is needed to avoid issues as the materials start accumulating inside the cooling tower.

What are the basics of Cooling Towers?

Once-through cooling allows water to be used once for cooling before it is discharged. Cooling towers allow the same water to be used repeatedly for cooling before it is discharged. What limits the number of times the same water can be used is solubility of various dissolved ions in the water. When concentrated high enough, some dissolved ions will become insoluble and start forming scale in the system. Typically, calcium carbonate is the first species to cause scale. For example, for a cooling tower system with a temperature change of 10 F and running at 3 cycles of concentration (cycles), one pound of makeup water gets used an average of 145 times before it is discharged via blowdown. That is much more efficient that one pound of water only being used once in once-through cooling.

As a yearly average, approximately 75% of the cooling action in a cooling tower results from evaporation, while 25% is transferred to the air through sensible heat.

Why is a Cooling Tower water treatment programme important?

Scale deposit, corrosion, fouling and biological proliferation on cooling towers can cause system downtime, loss of equipment efficiency, replacement of equipment, and can increase the risk of disease from pathogenic micro-organisms.

What is anaerobic digestion?

Anaerobic digestion uses bacteria to transform organic waste into energy in the complete absence of oxygen. This transformation occurs in nature, in marshes, for example. In order to be useable on a larger scale, the process has been tamed and optimized in closed tanks called digesters. The micro-organisms digest the organic fraction of the waste and convert it into biogas, a source of renewable energy. The residual organic matter (fraction not degraded during the process) forms the digestate that is dewatered, composted and used as a fertilizer by farmers.

Why anaerobic digestion?

With anaerobic digestion, Veolia is stepping away from the linear production and consumption approach and moving towards the circular economy, an economy in which the waste discarded by some systematically becomes valuable resources for others.

Read our article:

https://infrastructurenews.co.za/2023/01/19/metros-where-are-your-digesters/